This website uses its own operating cookies that will be installed. We also use third-party cookies:

- Google Analytics: used to collect statistical information about our website and perform marketing with Adwords.

- Zendesk: necessary for the operation of the online assistance chat.

As long as you don't accept, the third-party cookies will not be installed. More information.

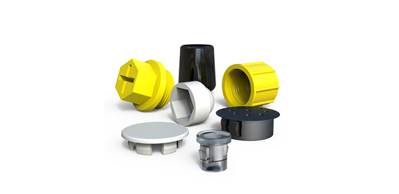

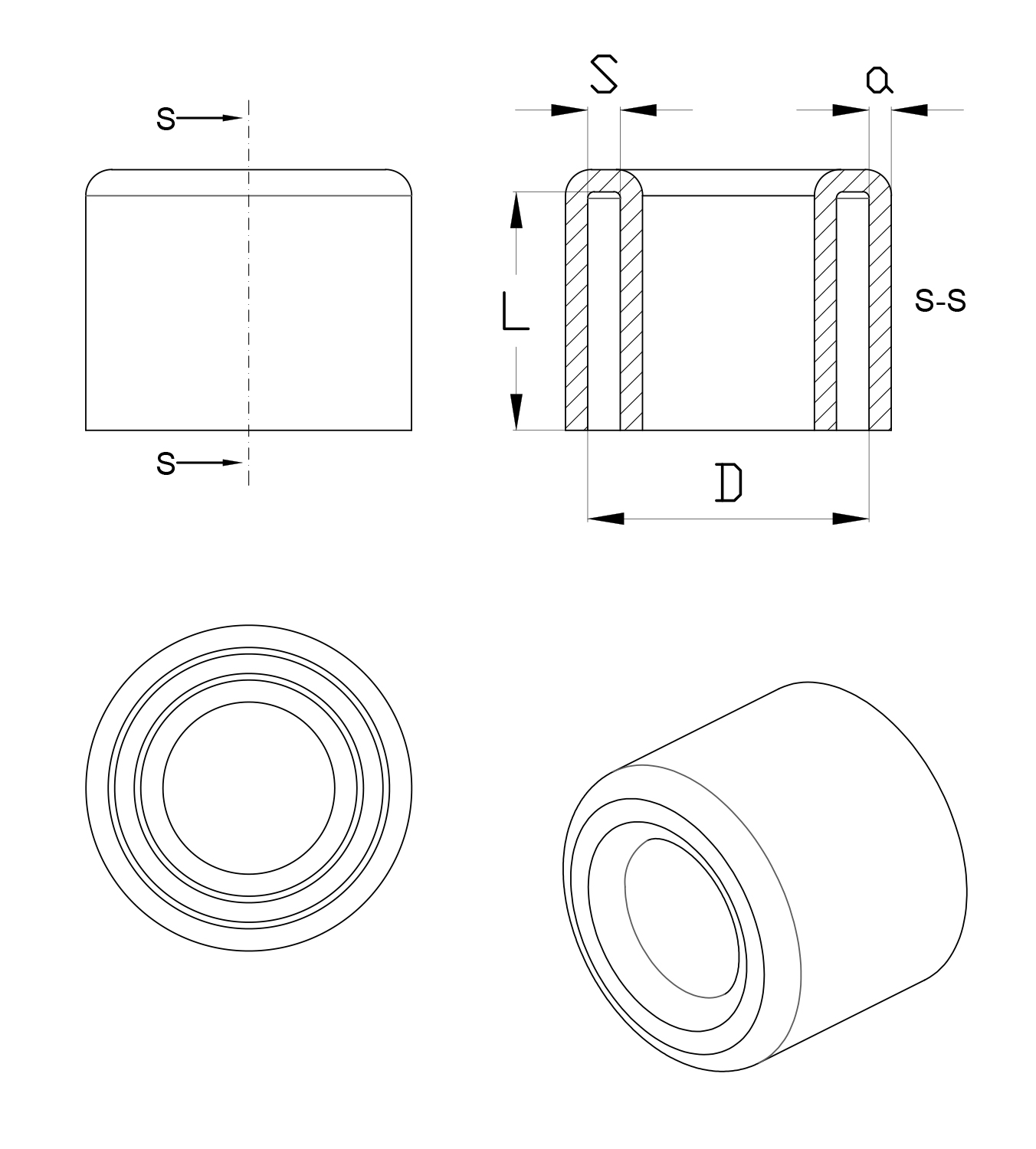

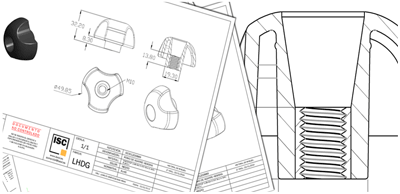

The material used for these caps is PVC plastisol (no phthalates) shore A 70º +/-5° with a use temperature of -15º to 60º. Parts manufactured in standard black color have ultraviolet (UV) protection without the need for special additives and are ideal if they are exposed to the elements. We also offer yellow and red colors as standard.

Upon special request we also offer:

*Other shore ranges between 50 and 90º.

*Pieces under FDA certification.

*Special vinyl material to comply with UL94 regulations.

Belgium

Belgium Deutschland

Deutschland España

España France

France Italia

Italia Nederland

Nederland Österreich

Österreich Polska

Polska Portugal

Portugal Schweiz

Schweiz U.K.

U.K. World Wide

World Wide